Moving from Prototype to Production: Practical Guidelines for Advancing Your Project

Transitioning from the prototype to production is a pivotal step in the product development journey, enabling the creation of high-quality and market-ready products. Typically, manufacturing enterprises must adhere to diverse quality standards as they strive to attain their objectives while simultaneously minimizing production expenses.

An effective program that spans from creating a prototype to delivering the final product allows you to bring your design concepts to life in the most optimal manner. This article provides guidance on navigating the process from prototype to production, offering practical tips for a seamless experience.

Before moving a prototype to the production process, there are several factors that a company must consider.

These include (but are not limited to):

• Test product demand: Crowdfunding makes it easier to see if people want your product.

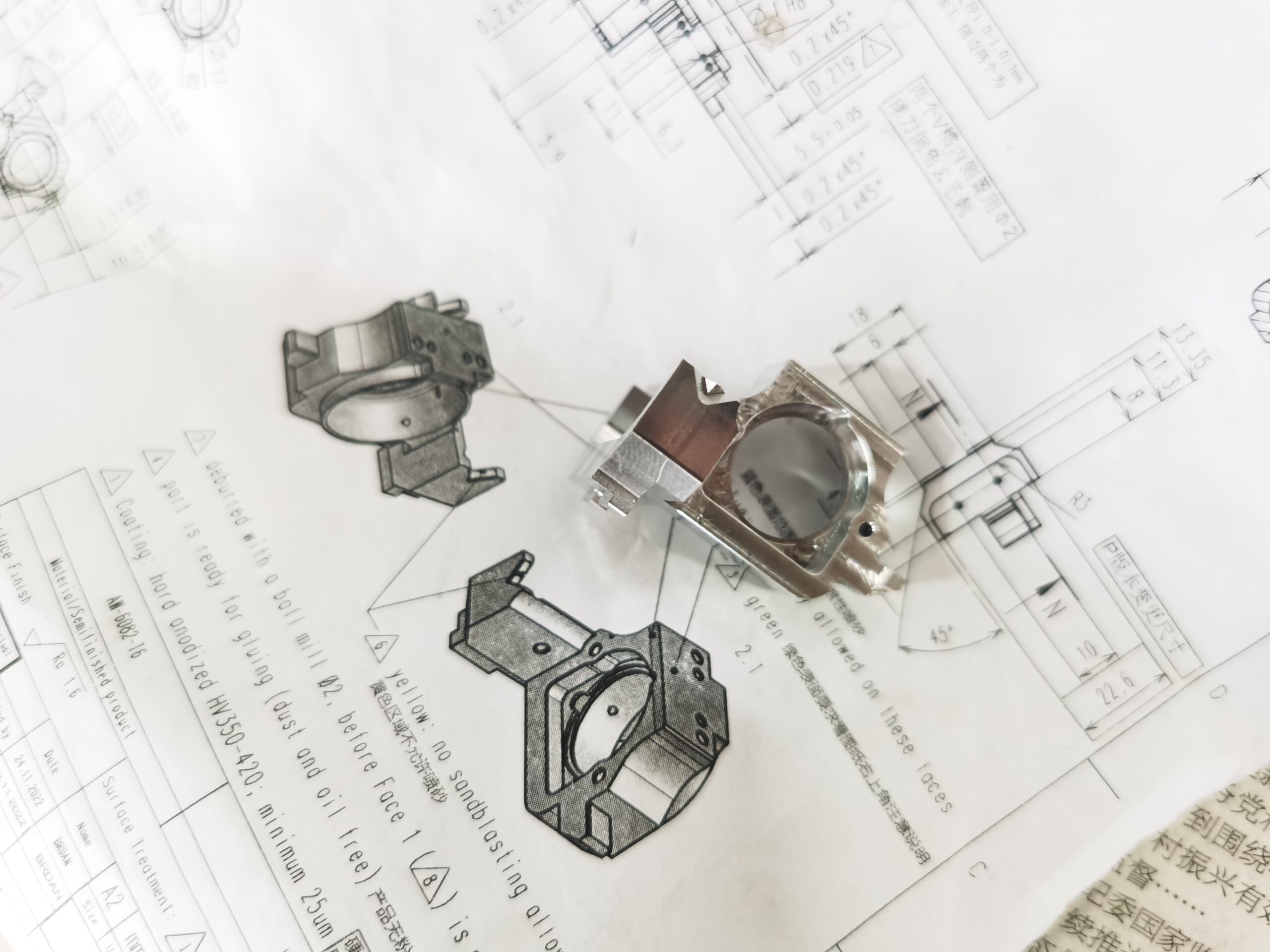

• Tooling, sampling, and non-production release involve creating a physical sample of the design that can be consistently replicated. This sampling process is an opportunity to make any needed changes before sending the product to mass production.

• Making sure the prototype is ready for mass production is important. The first prototype may need adjustments to ensure quality and design. Catching any flaws in this stage will save you time and money since you won’t need to make changes later in the process.

Mass Manufacturing, Producing & Scaling

Throughout the various manufacturing stages of the project, we coordinate communication to ensure that we implement the appropriate quality control measures. Communication is essential when leveling up production and scaling your business even further.

Ways to improve mass production and grow your business: be more efficient, expand, and explore new markets.

• Economies of scale: This reflects the cost savings when producing more of a product. This can come from large purchases of raw materials, production timelines, and more efficient employees.

• Continually improve upon production flows, inventory levels, order fulfillment, and demand forecasting.

• Being able to quickly replace problem products because of bad publicity, advertising, promotion, etc.

• Avoid supply chain shortages & delays.

• Being able to adjust production to surges in market demand.

What is the Significance of Having a Prototype Prior to Production?

Prototypes serve as the perfect embodiment of a design crafted before the completion of the final product. Their importance to production lies in simplifying the comprehension of the product. Prototype production stands out as a pivotal stage in the product development cycle. Additional advantages of prototype production encompass the following:

• Testing design features and incorporating additional elements;

• Confirming the functionality of the design;

• Identifying and rectifying design flaws prior to production;

• Gathering feedback from users;

• Establishing a tangible model for in-depth review and analysis.

Practical Guidelines for a Successful Transition from Prototype to Production

Consider the following factors to ensure a smooth progression from prototype to production.

• Select a Trustworthy Manufacturing Partner

It is crucial to collaborate with a dependable and seasoned manufacturing partner for optimal outcomes in prototype machining. While factors like costs, quality assurance and control, production timelines, and material availability are essential considerations, the selection of a reliable manufacturer should not be underestimated.

Conduct thorough research on prospective manufacturing partners. Request quotes from them and compare before making the appropriate choice for your project.

• Employ a Proof of Concept to Verify Product Design

Assuming a product is prepared for manufacturing without thorough scrutiny is a misconception. A fundamental guideline to bear in mind is that a manufacturer, well-versed in the manufacturing methods and necessary materials for producing a product, should not proceed without reviewing the design.

Hence, it is crucial to engage with parts suppliers and seek a “proof of concept.” This validation substantiates the assertions of the parts supplier, assuring that you are not venturing into a fruitless endeavor when bringing your product into production.

• Opt for the Right Materials and Manufacturing Process

Choosing the appropriate manufacturing process and materials marks a crucial initial step in both the prototype and production phases. Various production methods come with their own advantages and drawbacks. Nevertheless, factors such as budget, material characteristics, lead time, and quality often dictate the chosen manufacturing process.

When selecting materials, it’s imperative to recognize their significant impact on production costs and quality. Hence, scrutinize factors like cost, manufacturability, mechanical properties, and availability when making material choices.

• Develop a Functional Prototype

Advancing a product from the prototype to production stage hinges on creating a functional proof of concept. This facilitates testing and refining the design until it aligns with specifications, serving as a valuable tool for illustrations.

Updating 3D CAD files is crucial to ensuring alignment with tooling parts. Additionally, thorough testing of all components and the incorporation of essential features, such as assembly diagrams and guidance systems, are imperative.

• Prioritize Quality Assurance and Control

Testing stands out as a pivotal aspect in guaranteeing the quality of a prototype or production-ready product. It aids in identifying potential flaws or errors early on, enabling corrective measures before mass production and product launch.

Depending on the prototype development phase and product type, various tests can be employed to uncover potential flaws. For instance, usability tests evaluate the product’s user experience, while functional testing assesses its overall functionality.

FAQs

• Is creating a prototype expensive?

Developing a professional prototype can incur significant costs, ranging from 10 to 100 times the eventual price of the final product. The expense depends on factors such as the chosen production process, required efforts, and design complexity. However, opting for cost-effective materials, manufacturing methods, and a streamlined design can effectively minimize prototyping costs.

• Which steps are involved in transitioning from prototype to production?

The key manufacturing processes guiding the transition from prototype to production encompass design creation, prototyping, product development, and documentation.

• What defines a production prototype?

A production prototype is the final iteration of a product, crafted after rigorous testing and approval of the engineering prototype. This conclusive prototype verifies the flawlessness of a product’s design before progressing to mass production.

• Why is idea prototyping crucial before initiating mass production tooling?

Idea prototyping serves as a vital step before committing to mass production tooling. It allows engineers and product designers to gain a comprehensive understanding of the materials needed for mass tooling, ultimately aiding in determining the cost-per-unit for the large-scale production of the product.

Create Your Prototype Production With Fuyu Technology Today

When moving a prototype to production, there are many factors to consider. Having a manufacturing strategy is important for staying ahead in your industry. It shows what makes your company special and how to make sure you succeed.

Contact us today to create your manufacturing strategy.