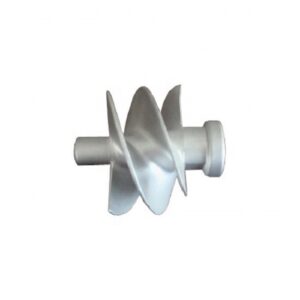

Precision Casting Polishing Rods Stainless Steel Parts for Home Fitness

Description

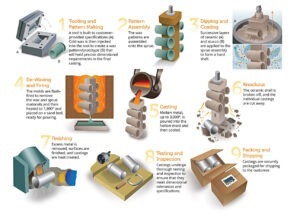

Investment casting, also known as “lost wax” or “precision” casting, involves creating a wax pattern that is attached to a sprue and dipped multiple times into a liquid ceramic slurry. After the ceramic material hardens, it adopts the internal shape of the casting. The wax is melted away, and molten metal is poured into the space previously occupied by the wax pattern. The metal solidifies within the ceramic mold, and the metal casting is subsequently extracted by breaking the mold.

➤Uses specialtv wax molds to create highly detailed and intricate models that capture every detail of the design

➤It can be used to create metal parts from steel, stainless steel, aluminum, nickel and other materials

| Process | Investment casting / Precision casting / Lost wax casting | |

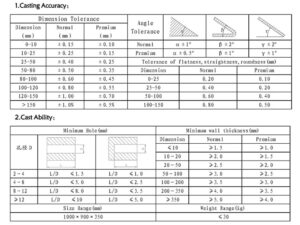

| Processing Capacity | Dimension of Size | Max. Size 15 x 12 * 8 inch |

| Tolerance | ISO8062 ISO2768 | |

| Wall Thickness Tolerance | 0.01 ~ 0.015 (0.25mm ~ 0.375mm) | |

| Angularity | 0.5° ~ 1° | |

| Material | Carbon steel and most steel alloys, brass, bronze, copper, aluminum, and Stainless Steels including Duplex 2205, 2507, and others. | |

| Surface Treatment | Mill Finishing, Anodizing, Powder Coating, Polishing, Brushing, Electrophoresis, Electroplating, Laser Marking, etc. | |

| Advantages | ➤Highly-detailed end products that require minimal finishing/detailing ➤Smooth surface finishes ➤Compatibility with most metals ➤Accuracy in terms of dimensionality and surface details |

|

| Drawing format | IGES, STEP, AutoCAD, Solidworks, STL, PTC Creo, DWG, PDF, etc. | |

| Application | Turbine blades, medical equipment, firearm components, jewelry, golf club heads, gears, pulleys, valve components, doorknobs, medical tooling and equipment, auto parts and components, airplane parts, kitchenware, utensils, cookware, gearbox cases, automotive cylinder heads, cylinder boxes, pipes, tubes, assemblies, plus many other machine components — anything with complex geometry benefits from this technology. | |

Company Profile

|

|

|

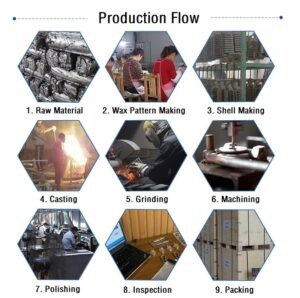

Production Process

Before production, we will evaluate and highlight the technical requirements, including: material, surface treatment, hardness, weight, important technical requests and customer’s special requests. Meanwhile, we will establish files for each customer, including: technical documents, communication records and the time of technique requests changes, this will help us to provide guarantee for product inspection.

|

|

|

Name: Glass Clamp |

Name: Bearing Housing |

Name: Machinery Parts |

Name: Pipe Fitting |

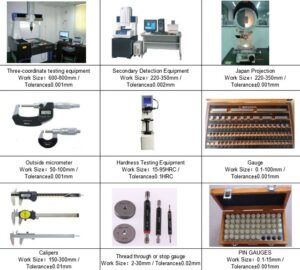

Quality Inspection Tools

Why Choose Us

Our Core Values:

> Continuous Improvement

Our Quality:

Our Service:

Packaging

|

|

|

Shipping Methods

|

|