Description

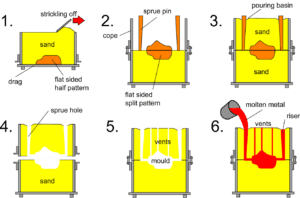

Sand casting is the most widely used metal casting process. Material is heated to its melting point before being poured into a mold to cool and solidify. This process offers exceptional design flexibility and allows manufacturers to create high-complexity shapes. The tooling involved is low-cost and material options are abundant.

➤Molds are made from mixtures of sand and clay

➤Works well with a variety of ferrous and non-ferrousmetals

| Process | Sand casting | |

| Processing Capacity | Dimension of Size | Max. Size 15 x 12 * 8 inch |

| Tolerance | ISO8062 ISO2768 | |

| Wall Thickness Tolerance | 0.01 ~ 0.015 (0.25mm ~ 0.375mm) | |

| Angularity | 0.5° ~ 1° | |

| Material | Alloy Steel, Aluminum, Brass, Bronze & Copper, Cast Iron, Grey, Ductile & White Iron, Magnesium, Stainless Steel/ Duplex 2205, 2507 & Zeron | |

| Surface Treatment | Mill Finishing, Anodizing, Powder Coating, Polishing, Brushing, Electrophoresis, Electroplating, Laser Marking, etc. | |

| Advantages | ➤Lower costs for low-volume production runs ➤Suitability for fabricating large parts and components ➤Sand casting works well with a variety of ferrous and non-ferrous metals ➤Shorter lead time compared to other processes |

|

| Drawing format | IGES, STEP, AutoCAD, Solidworks, STL, PTC Creo, DWG, PDF, etc. | |

| Application | Axles, Engine blocks, Exhaust manifolds, Gearboxes, Impeller housing, Pistons, Pumps, Turbine housings | |

Company Profile

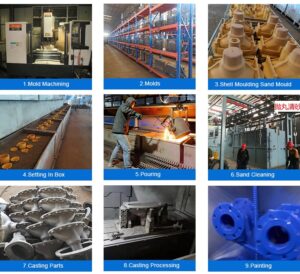

Production Process

Before production, we will evaluate and highlight the technical requirements, including: material, surface treatment, hardness, weight, important technical requests and customer’s special requests. Meanwhile, we will establish files for each customer, including: technical documents, communication records and the time of technique requests changes, this will help us to provide guarantee for product inspection.

Technical Features:

1. Suitable for making blanks with complex shape, especially with complex innercavity;

2. Wide adaptability and low cost;

3. For some materials with poor plasticity, such as cast iron, sand casting is the only forming process to manufacture the parts or blanks.

|

|

|

Name: Glass Clamp |

Name: Bearing Housing |

Name: Machinery Parts |

Name: Pipe Fitting |

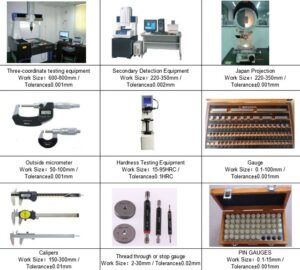

Quality Inspection Tools

Why Choose Us

Our Core Values:

> Continuous Improvement

Our Quality:

Our Service:

Packaging

|

|

|

Shipping Methods

|

|