Description

Die castings are characterized by very good surface finish and dimensional capacity. Parts produced using a die cast process are typically thinner-walled and smoother than those produced by the sand casting process.

➤Die casting uses tool steel molds to create castings from softer metals like zinc and aluminum

➤Used for small and intricate pieces that need to be produced in large quantities or over a long period of time

| Process | Die casting | |

| Processing Capacity | Roughness | Ra1.6-Ra3.2 |

| Tolerance | GB/T6414-1997, IS08062:1994 | |

| Maximum size | ≤1200mm×800mm×400mm | |

| Weight range | 0.1Kg-120Kg | |

| Material | Aluminum, Magnesium alloys, Zinc, Copper | |

| Secondary Operations | Trim press, drill and tap, CNC, polishing, buffing, vibratory finish, shot blasting | |

| Surface Treatment | Sand Blasting, Polishing, Spray painting, Pad Printing, Colour Electrophoresis, Mirror Finishing, Silk-Screen Printing, Oxidation | |

| Advantages | ➤Manufacturers can produce intricate parts with thin walls and fine features ➤Production is fast and cost-effective ➤Finished products have a high degree of stability and dimensional accuracy, as well as a good surface finish |

|

| Drawing format | IGES, STEP, AutoCAD, Solidworks, STL, PTC Creo, DWG, PDF, etc. | |

| Application | Mechanical Components/parts, Boat parts and Marine hardware, Construction hardware, Auto parts and accessories, Medical Instrument parts, pump & valve parts and accessories, Impellers and propellers(propellors), Pipe Fittings or pipeline accessories, Other industry metal casting parts | |

Company Profile

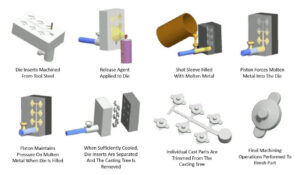

Production Process

Before production, we will evaluate and highlight the technical requirements, including: material, surface treatment, hardness, weight, important technical requests and customer’s special requests. Meanwhile, we will establish files for each customer, including: technical documents, communication records and the time of technique requests changes, this will help us to provide guarantee for product inspection.

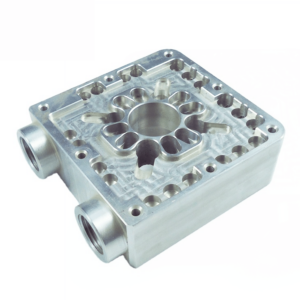

Name: Motor Parts |

Name: Led Downlight Housing |

Name: Pressure-reducing Valve |

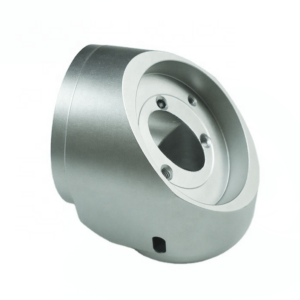

Name: Motor Housing Front Cover |

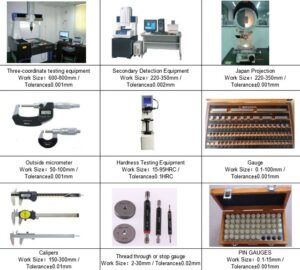

Quality Inspection Tools

Why Choose Us

Our Core Values:

> Continuous Improvement

Our Quality:

Our Service:

Packaging

|

|

|

Shipping Methods

|

|