Plastic Machining Process

Plastic CNC machining is a method of subtractive manufacturing where a block of plastic is positioned in relation to a moving cutting tool, which is then used to subtract material from the block. The operation is directed by a digital file that dictates the cutting tool’s trajectory, ensuring the end product conforms to the specified design.

The use of CNC for fabricating plastic parts and components is a prominent trend in manufacturing, attributed to the process’s capacity to deliver parts that are consistently precise, with high fidelity to the original specifications and tight tolerances.

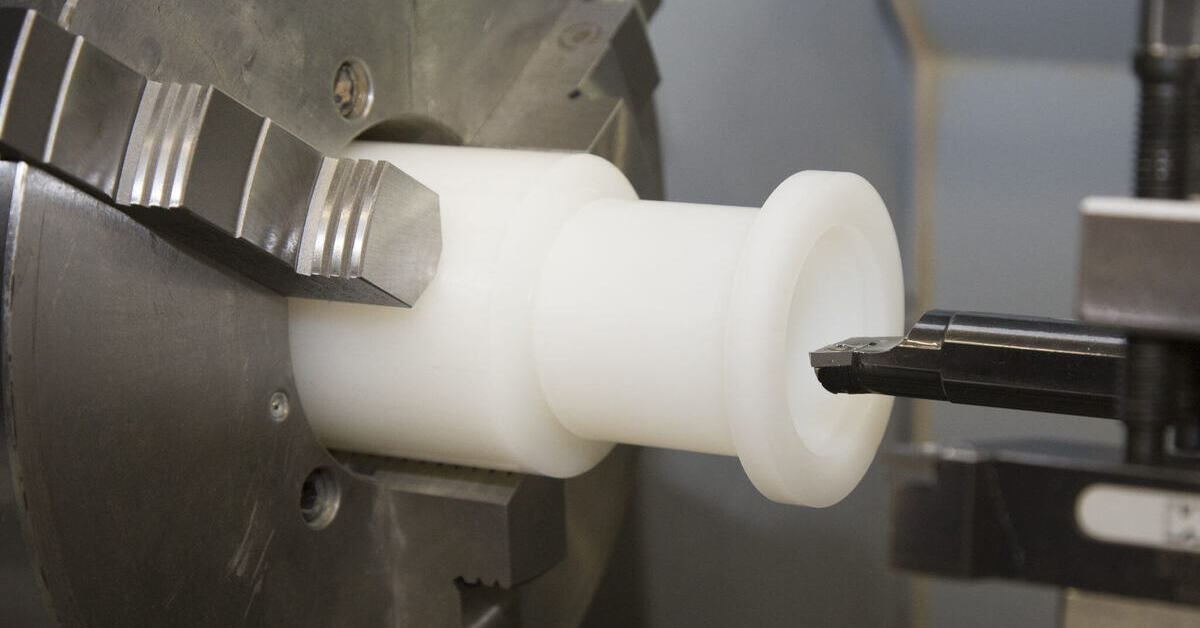

In the plastic turning process, the workpiece is rotated, enabling a fixed cutting tool to accurately trim away surplus material, thereby sculpting the piece according to the specified design.

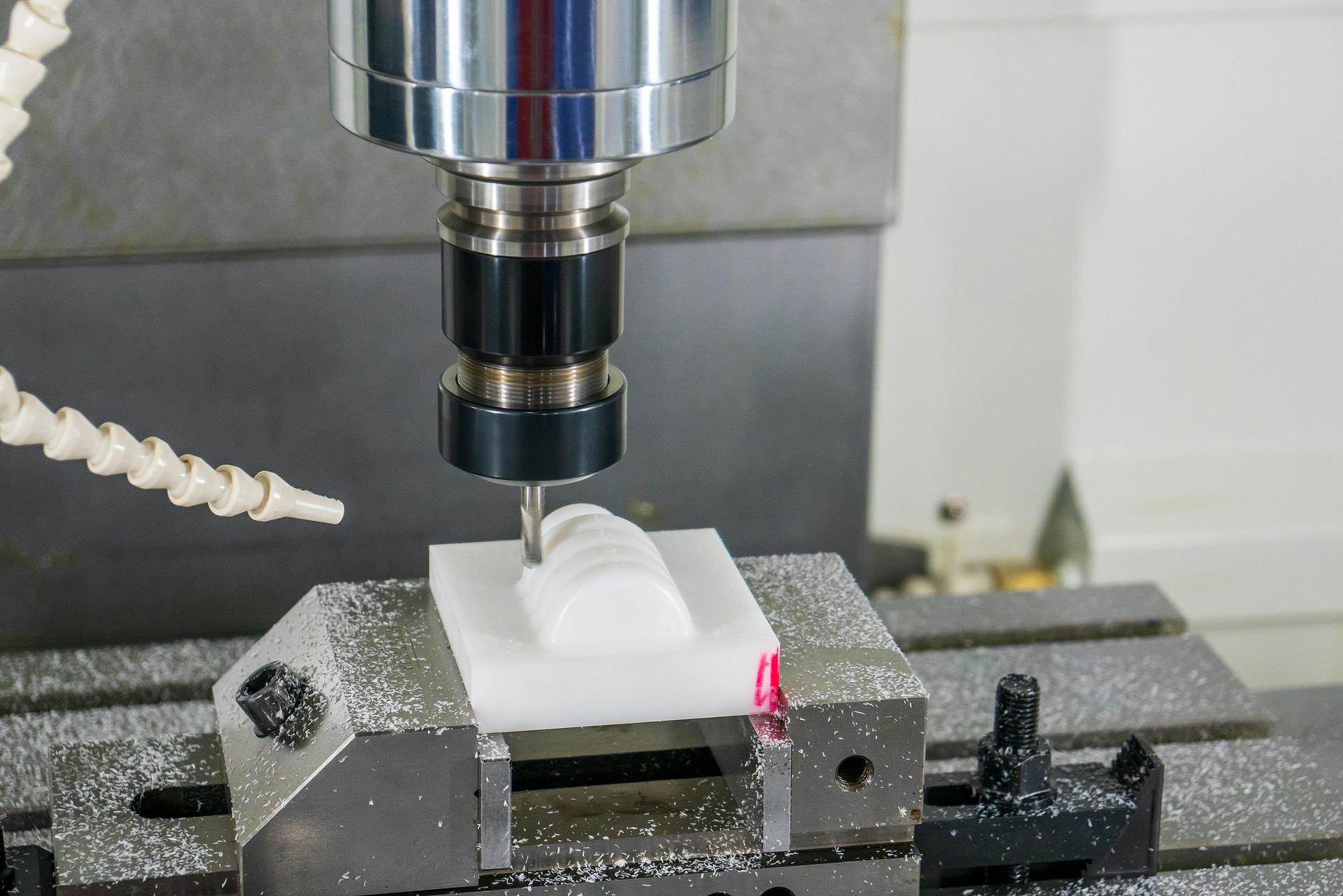

Plastic CNC milling involves affixing the workpiece to a platform, while a rotating spindle secures the cutting instrument to precisely eliminate plastic from various angles.

Advantages Of CNC Plastic Machining

Mold-free

Without the need for molds, plastic CNC machining stands out for its ability to efficiently produce prototypes and limited-run items. This method avoids the costly metal tooling required for injection molding, thus cutting down on production time and expenses.

Tight Tolerances

Offering tighter precision, plastic CNC machining is the go-to for components demanding high accuracy. Its superior precision and consistency outperform injection molding and 3D printing, making it ideal for sectors that require stringent tolerance levels.

Wide Range of Materials

Plastic CNC machining boasts an impressive selection of materials, due to the superior structural qualities of engineering-grade plastics, such as electrical insulation and strength-to-weight ratio. This enables a broader material choice in plastic fabrication, including favorites like HDPE, ABS, Nylon, Acrylic, Delrin, PEEK, and more.

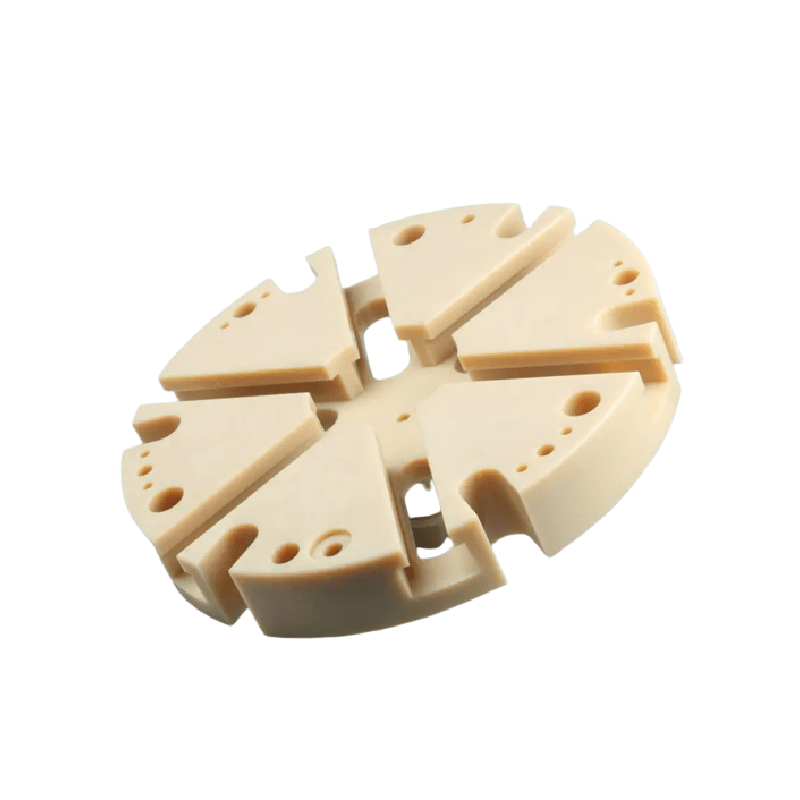

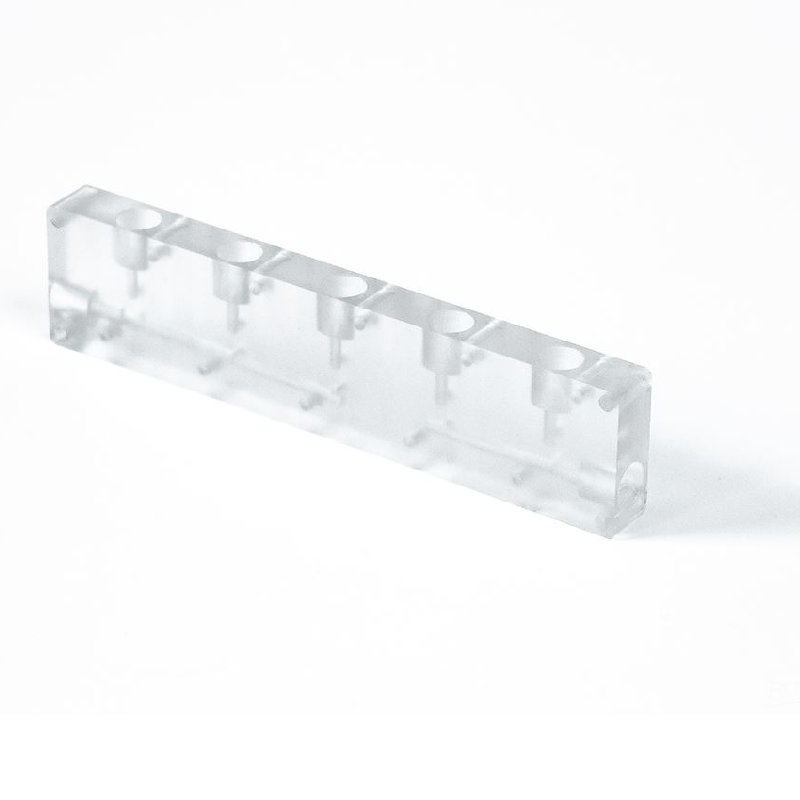

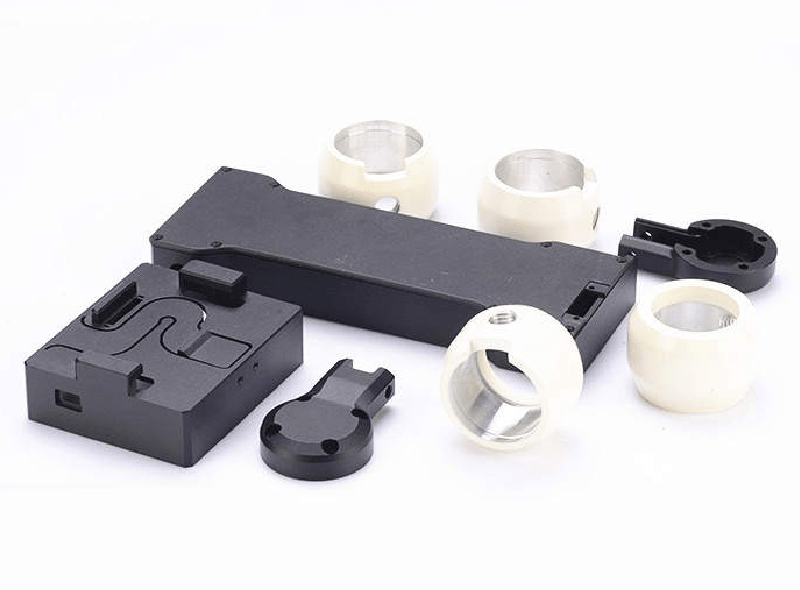

Custom Plastic CNC Machined Parts We Provided

Dedicated to delivering excellence, our CNC machining service is designed to meet a wide range of needs, offering reliable and efficient solutions on a global scale. Whether you need customized CNC aluminum parts or precise machining for unique specifications, our team of experts ensures precision and reliability in every project.

When To Use CNC Machining Instead Of 3D Printing?

Material Types

For components designed in materials like PVC, POM, PEI, or PEEK, 3D printing isn’t a viable method. These materials, however, are available in block and bar form and are suitable for CNC machining.

Complexity of Parts

CNC machining stands out as the preferred method for parts necessitating fine details beyond the capabilities of 3D printing. For instance, creating small, intricate optical patterns with a radius as minute as R 0.05 mm is achievable through CNC machining, a feat challenging to accomplish with 3D printing.

When Manufacturing Large Plastic Components

Producing large plastic components through 3D printing is not practical, as the process is time-consuming, often extending for hours. On the other hand, creating large components with a CNC mill is considerably faster, taking just a few minutes.

Precision Manufacturing

For producing parts with high precision and complex details, CNC machining surpasses 3D printing. It achieves exceptional accuracy, with tolerances as tight as ±0.005mm, whereas 3D printing’s accuracy ranges between ±0.1 to ±0.5mm.

FAQ You May Concerned

Plastic CNC machining involves utilizing computer numerical control (CNC) machinery to mold and slice plastic materials into specific configurations. This method boasts remarkable precision, facilitating the creation of elaborate patterns featuring intricate details or sophisticated geometrical shapes.

The expense involved in plastic CNC machining is influenced by numerous elements, such as the type of material utilized and the proficiency of the machining service provider or CNC milling workshop. Nonetheless, prices can start from as minimal as $10 per hour.

Acetal, PEEK, and PVC stand out as the top choices for machining due to their excellent machinability and reliable dimensional stability. Additionally, these plastics are easily accessible at an affordable price and are characterized by their ability to withstand chipping and melting. Their resistance to impact and high impact strength further contribute to their suitability for machining applications.