Knurling Process: Understanding Its Types, Tools, And Finishes

What is Knurling?

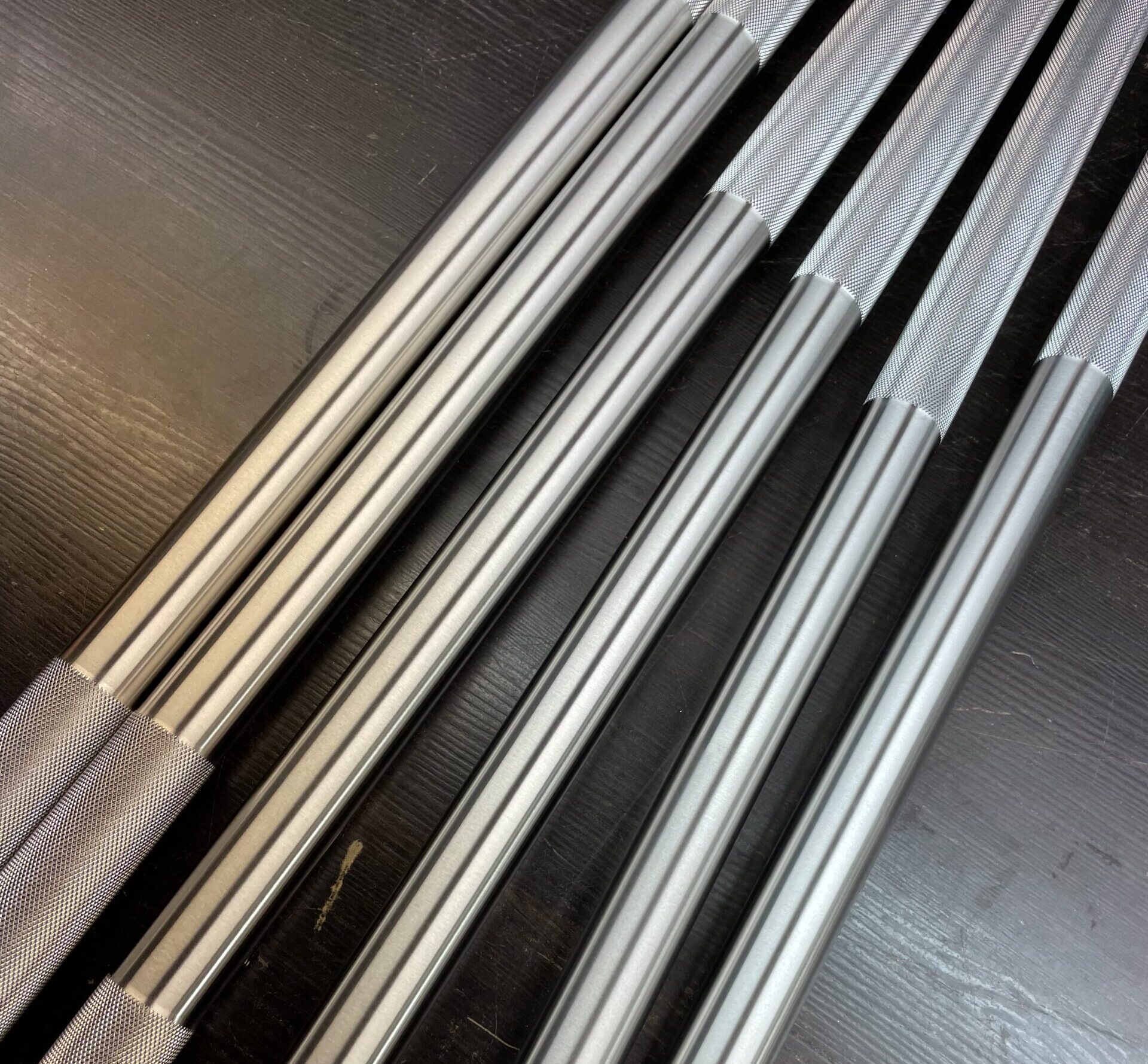

Knurling stands as a versatile machining process designed to impart a textured surface onto a workpiece. This texturing is achieved by rolling two serrated wheels—known as knurling wheels—against the workpiece, creating a pattern that enhances grip and facilitates ease of handling. The knurled finish is commonly utilized on handles, knobs, and other components requiring enhanced traction.

Types of Knurling Techniques

SLinear Knurling: This technique involves creating straight or diagonal lines on the workpiece, often employed for aesthetics and functionality. It is widely used on cylindrical or flat surfaces.

Radial Knurling: In contrast, radial knurling forms a circular pattern on the workpiece. This technique is chosen for components where a circular texture is preferred, such as for ergonomic grips.

Different Knurling Tools for Knurled Finish

Single-Wheel Knurling Tools: These are simple and effective for linear knurling on cylindrical surfaces.

Double-Wheel Knurling Tools: Ideal for radial knurling, these tools create a circular pattern by using two knurling wheels.

Circular Knurling Tools: Employed for intricate designs, circular knurling tools can create custom patterns on a variety of surfaces.

Common Defects of Knurling Operations

Incomplete Knurling: This occurs when the knurling wheels fail to cover the entire workpiece, often due to insufficient pressure or improper alignment.

Overlapping Patterns: Overlapping patterns can result from excessive pressure or a misalignment of the knurling wheels.

Uneven Textures: Inconsistent pressure, incorrect tool choice, or improper lubrication can lead to uneven textures on the knurled surface.

Tips for Achieving the Best Knurled Finish

Optimizing Feed Rate and Pressure: Adjusting the feed rate and pressure ensures proper engagement of the knurling wheels with the workpiece, contributing to a uniform finish.

Lubrication: Proper lubrication is crucial for reducing friction and heat during the knurling process, preventing defects and ensuring a smooth texture.

Tool Selection: Choosing the right knurling tool based on the desired pattern and material is essential for achieving the best results.

Material Considerations: Different materials respond differently to knurling. Understanding material properties helps in selecting the appropriate tools and settings.

Conclusion

In conclusion, knurling is a nuanced machining process offering diverse applications in enhancing the functionality and aesthetics of components. Whether opting for linear or radial knurling, selecting the right tools, and addressing common defects, manufacturers can consistently achieve high-quality knurled finishes. The intricate dance of feed rates, pressure, and tool selection plays a pivotal role in the success of knurling operations, emphasizing the need for a nuanced approach to this essential machining technique.

FAQs

1. What materials are suitable for knurling?

Knurling is applicable to various materials, including metals like aluminum, steel, and brass, as well as certain plastics.

2. Can knurling be applied to irregularly shaped objects?

Yes, knurling tools are designed to adapt to different shapes, allowing for the application of knurled patterns on irregular surfaces.

3. How does knurling affect the overall durability of a component?

Knurling enhances grip without compromising the structural integrity of the material, contributing to improved durability.

4. Are there alternatives to traditional knurling methods?

Yes, modern CNC machining techniques offer alternative methods for achieving textured surfaces, though traditional knurling remains a widely used and effective approach.

This comprehensive exploration of knurling provides valuable insights for both novice and experienced machinists, offering guidance on techniques, tools, and troubleshooting common issues.

You Are Interested In: