Our Precision Die Casting Services

If you require custom metal parts, Fuyu is here to assist you as a die casting service provider. Since 2009, we have upheld our engineering team and equipment to rigorous standards to consistently produce robust and durable parts and prototypes. Our stringent die casting processes guarantee that your custom specifications are met, ensuring exceptional quality. We offer two types of die casting capabilities to fulfill your needs.

Hot Chamber Die Casting

Hot chamber die casting, also referred to as gooseneck casting, is a rapid process typically completed within 15 to 20 minutes per casting cycle. This method facilitates high-volume production of relatively intricate parts. It is particularly suitable for zinc alloy, lean alloys, copper, and other alloys with low melting points.

Helps in quicker production – like for minor components, produces up to 18,000 shots per hour

Builds parts with less porosity

It can create metal components with a more intricate design

It brings the lowest wastage

Longer life due to low melting point

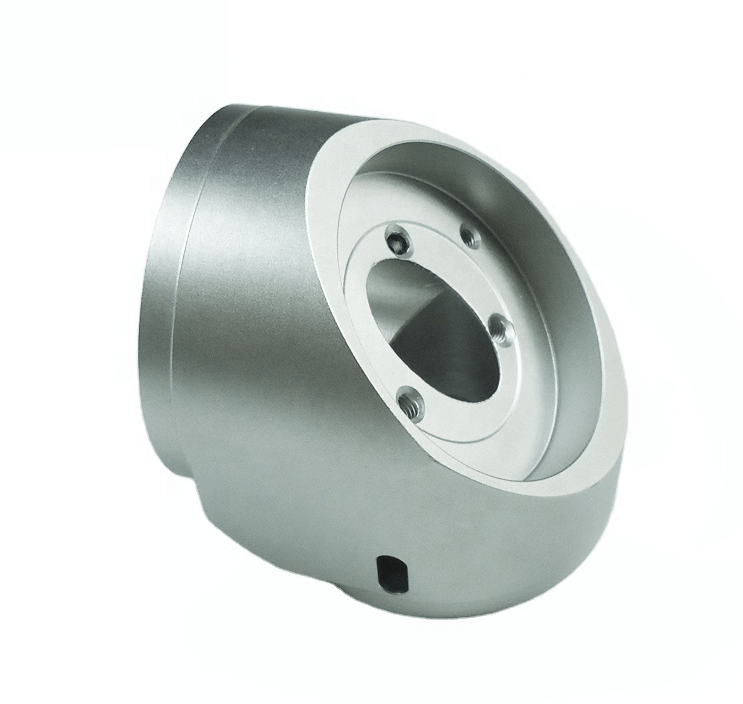

Cold Chamber Die Casting

The cold chamber die casting process is crucial for minimizing heat accumulation and addressing corrosion issues in the machine’s plunger and associated components. This method is predominantly employed for alloys with high melting points, such as aluminum, magnesium, select copper alloys, and ferrous alloys.

Better strength

Thicker metal castings due to advanced pressure during injection

Lower maintenance cost

It gets excellent dimensional precision to the part

Potential high-speed production.

Simple-to-carryout operation.

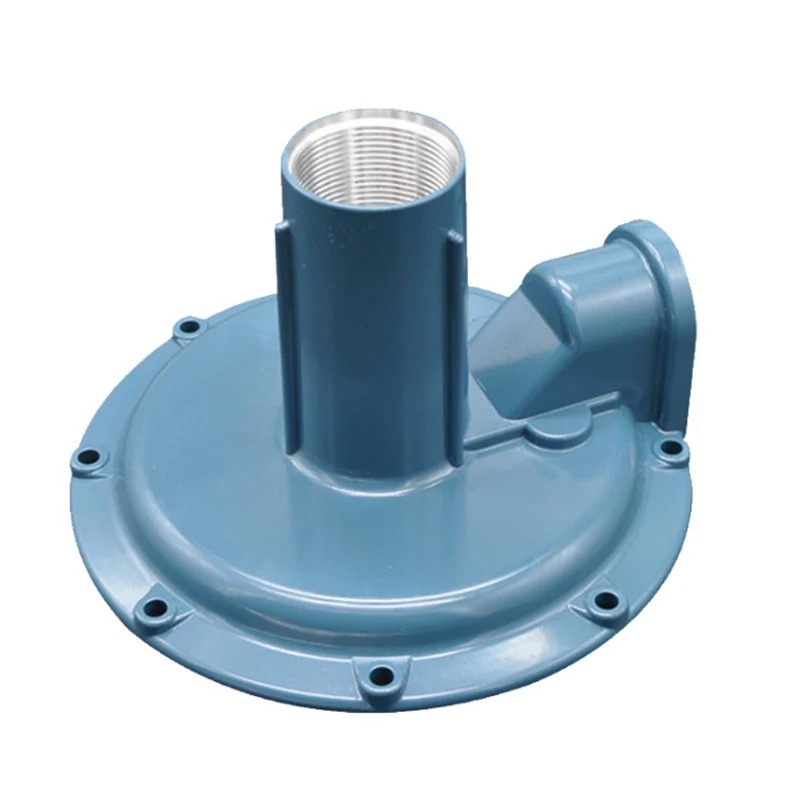

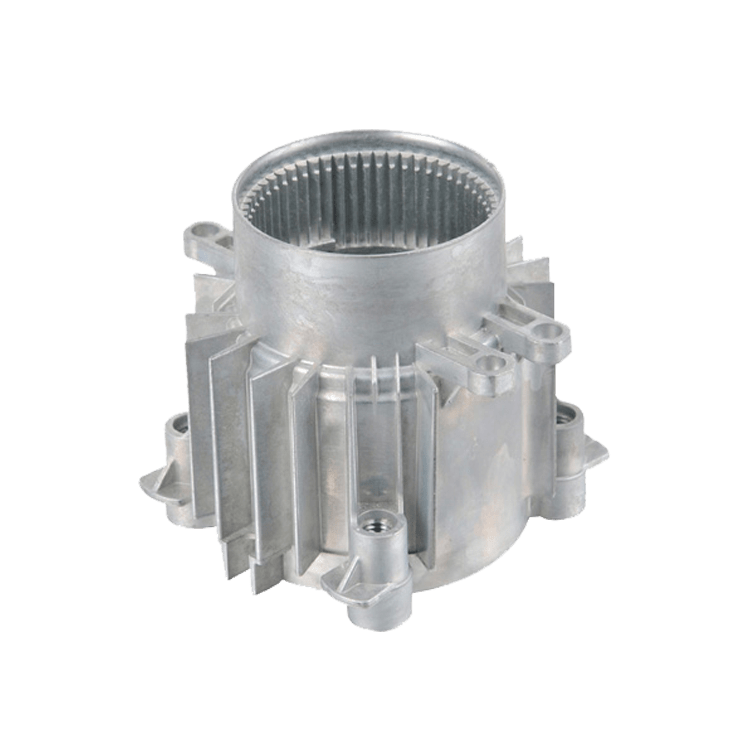

Applications of Die Casting

The versatility and significant production capacity of die casting make it suitable for a wide range of applications across various industries. Typically, die casting is well-suited for small to medium-sized products with intricate features. Examples include consumer goods, industrial products, automotive components, aerospace parts, and medical device components. Die casting is an excellent choice for high-volume metal parts, especially when the parts may be too large for similar high-volume processes like Metal Injection Molding (MIM).

Aerospace & Automotive Components

Connector Housings

Pumps and Plumbing Fixtures

Gears

Outdoor lighting

Appliances and Lighting

Custom Die Casting Parts We Offered

If you have a complex part design, Fuyu can assist you in bringing it to fruition. Equipped with the appropriate machinery, extensive technical expertise, and a commitment to excellence… From tool design through to finishing and final shipment, Fuyu guarantees meticulous attention to detail, ensuring each project meets stringent quality standards and your orders are consistently delivered punctually.

Die Casting from Prototyping to Production

Die casting stands as a highly efficient approach to crafting superior prototypes and small-batch components, rendering it a prime option across diverse applications. We are poised to aid you in realizing your manufacturing goals through our proficient die casting services.

Prototyping

A cost-effective and streamlined approach to crafting top-notch prototypes. This technique employs economical tooling, thereby providing a budget-friendly means to fabricate prototypes with flexibility for material options and design alterations.

Market Testing

We assist in the creation of die casting products tailored for market and consumer testing, concept models, and user evaluation. With our die casting services, you can swiftly implement changes for additional testing and market introduction.

On-Demand Production

A cost-effective and streamlined approach to crafting top-notch prototypes. This technique employs economical tooling, thereby providing a budget-friendly means to fabricate prototypes with flexibility for material options and design alterations.

Challenges experienced within the existing supply chain?

—— Why Choose Fuyu

Collaborating with us provides you with access to premier CNC manufacturing services in China. We assure high-quality custom machining solutions that adhere to the most rigorous industry standards.

Unsatisfactory Quality

The quality of products delivered by existing suppliers does not meet their expectations or standards.

Dimensional Deviations

Internal Defects like Flash, Burr, Sink Marks, scratches, pits, or stains.

Heat Treatment Issues

Surface Coating Problems

Delivery Delays

The existing supplier fails to deliver the product as agreed, you may face production line disruptions or other problems.

Adherence to agreed-upon delivery timelines is crucial. We are always optimizing logistics and production processes to ensure on-time deliveries, minimizing disruptions for the customer.

Poor Customer Service

The existing suppliers with poor customer service, poor communication or lack of timely response.

We aim to establish transparent communication channels, provid prompt responses, and address customer concerns are vital for effective customer service.

Technical Capabilities

The supplier is unable to provide the required technical capabilities or innovative solutions

Staying updated on technological advancements and investing in relevant capabilities are crucial for us. We aim to provide innovative solutions and adapt to evolving technical requirements.

Changes in Requirements

A customer’s business needs may change over time. And the current supplier is unable to adapt to these changes or provide flexibility

Flexibility is key to accommodating changing customer requirements. We are able and willing to adapt to customer’s business needs and offer tailor solutions.

Price Competitiveness

Reevaluate current relationship with a supplier because of a more affordable supplier or due to changes in market prices.

Regularly reviewing and adjusting pricing strategies is essential for customers to remain competitive. We offer cost-effective solutions and transparent pricing to improve customer satisfaction.