What Is CNC Machining? 6 of The Most Common CNC Machines

CNC (Computer Numerical Control) technology has revolutionized the manufacturing sector by enhancing efficiency, accuracy, and consistency beyond manual capabilities. This guide delves into the dynamic world of CNC machinery, highlighting its essential role in modern manufacturing, explaining the various types of CNC machines, and showcasing their unique functionalities.

CNC machining stands as a pivotal advancement in the manufacturing industry, controlled by sophisticated computer programs. These programs command the machinery to perform precise operations, making previously impossible tasks attainable and straightforward. The versatility of CNC machining is evident in the myriad of components produced, catering to a wide array of applications across different sectors.

CNC machining is a process where pre-programmed software dictates the movement of factory tools and machinery. This automation allows manufacturers to craft parts with high precision, minimizing waste and eliminating human error. The capability to produce intricate parts accurately is especially beneficial in bulk production.

Types of CNC Machines

CNC Milling Machines

One of the most prevalent CNC tools, CNC mills operate through computerized controls to cut materials into desired shapes and sizes. Employing G-code, these machines perform various operations such as drilling, tapping, and milling. Renowned for their versatility, CNC mills usually come in configurations ranging from three to six axes, with manufacturers including Okuma, HAAS, and DMG Mori leading the market.

CNC Lathes

CNC lathes excel in cutting workpieces as they rotate, making clean, precise cuts swiftly. These machines are integral for tasks requiring high precision and are designed to be more compact than their milling counterparts. They are capable of understanding both G-code and proprietary languages, with brands like HAAS and Okuma being prominent producers.

CNC Plasma Cutters

Specializing in cutting heavy materials like steel, CNC plasma cutters employ a high-speed gas blown from a nozzle, creating plasma hot enough to melt the workpiece material. These machines are adept at processing two-dimensional shapes.

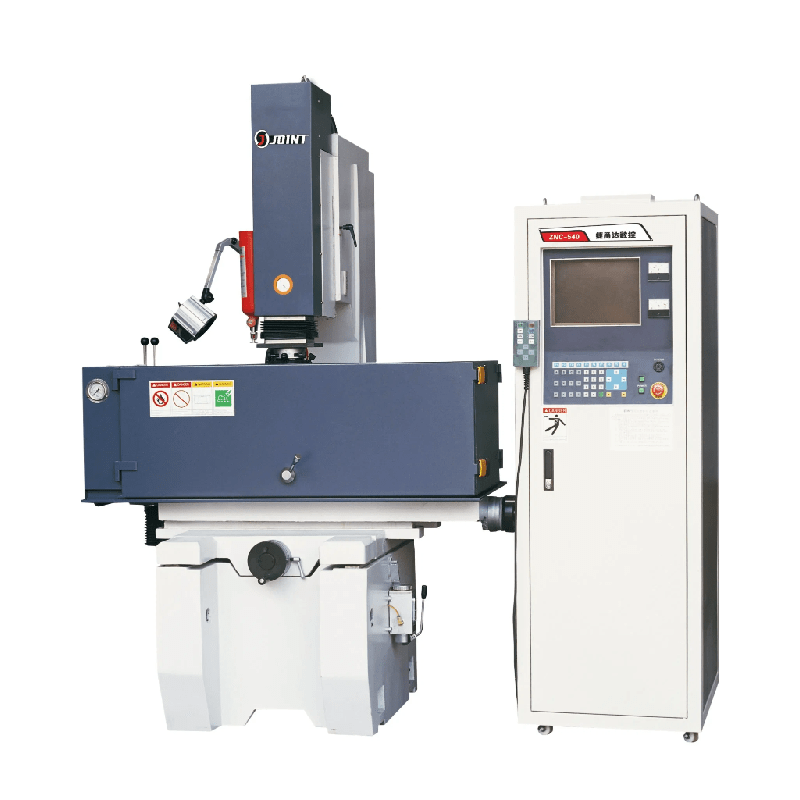

CNC Electric Discharge Machines (EDM)

EDM utilizes electrical discharges to sculpt precise shapes within a material, with the process removing material from the workpiece through recurrent electrical sparks.

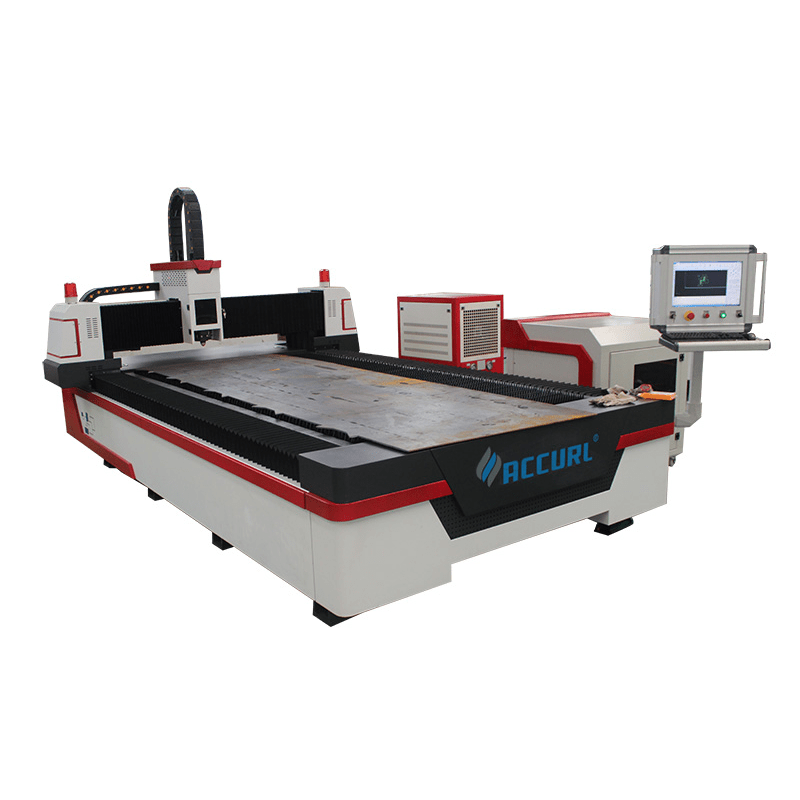

CNC Laser Cutters

Similar to plasma cutters but employing a laser for cutting, these machines are versatile in cutting metals, plastic, or hardwood with adjustable laser intensity based on material properties.

The Impact of CNC Machining in Industries

You may find yourself curious about the outputs of CNC (Computer Numerical Control) machining. This highly automated process plays a crucial role in generating components vital for a myriad of sectors:

1. Transport Sector: CNC technology is instrumental in fabricating various parts for modes of transport such as cars, heavy-duty trucks, rail systems, and maritime vessels. This includes manufacturing intricate items like brake systems, motor parts, exterior lighting enclosures, and more.

2. Defense Industry: The defense sector heavily relies on CNC machines for producing essential components used in armored tanks and sophisticated communication devices.

3. Aerospace Industry: Given the demanding conditions of aerospace environments, CNC machined components are preferred for their exceptional precision. These parts are critical for enduring high velocities and intense atmospheric pressures, underscoring the reliance of this sector on CNC manufactured items.

4. Medical Field: Precision is paramount in the medical industry, and CNC machines meet this requirement by producing a wide range of medical devices. This encompasses everything from surgical instruments and bespoke orthotics to implantable devices, highlighting CNC machining’s pivotal role in modern healthcare.

5. Electronics Manufacturing: The advancement of electronic technology owes much to CNC machining, with its application extending to the creation of semiconductors, circuit boards, and casings for laptops, among others.

Conclusion

CNC machines have drastically reshaped manufacturing, delivering parts essential for sectors such as transportation, defense, aerospace, medical, and electronics. The precision and efficiency of CNC machining have been instrumental in advancing technology and supporting industries that require utmost accuracy.

By understanding the transformative power of CNC machining, manufacturers can leverage these technologies to enhance production, optimize efficiency, and foster innovation in product development.

FAQs – CNC Machining and CNC Machines

Q1: What is CNC?

A1: CNC stands for Computer Numerical Control, a technology used in automated machining processes.

Q2: What materials can CNC machines work with?

A2: CNC machines can work with metals, woods, plastics, foam, glass, and composites.

Q3: What industries benefit from CNC machining?

A3: Industries like aerospace, medical, electronics, defense, and transportation greatly benefit from CNC machining.

Q4: How do CNC machines achieve precision?

A4: CNC machines are programmed with specific tolerances, allowing minimal variance and high precision in the dimension of parts.

Q5: Can CNC machines operate with different software?

A5: Yes, CNC machines primarily use G-code but can also interpret other proprietary programming languages.

Learn more about our CNC Machining capability, visit https://fuyutechnology.com/cnc-machining/